- Cad cam program full#

- Cad cam program software#

- Cad cam program code#

- Cad cam program trial#

This feature automatically avoids part tip-ups on the plate without the need for a full head raise, thereby drastically reducing the cut-to-cut cycle time.

Cad cam program software#

Are there other ways to increase productivity?Īsk whether the software supports collision avoidance. This architecture will ensure that you only pay for the features and options that you actually need. You may benefit from purchasing a software package that is flexible or modular in nature.

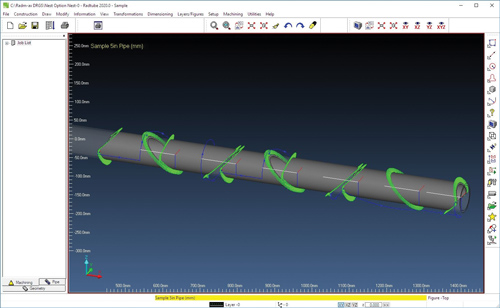

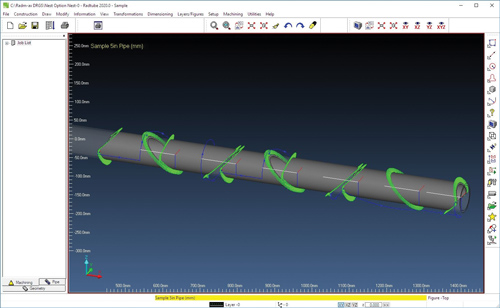

In addition, if you use 3D CAD to create parts, you may want to consider whether the software supports direct 3D CAD import. However, advanced software also comes equipped with its own integrated 2D CAD program and/or variable shape parts library. Nearly all CAD/CAM nesting programs can import standard DXF and DWG CAD files. What about part creation and CAD import?.

Cad cam program trial#

Find out how the software handles these aspects of the job, or request a free trial with production capability enabled and test it out for yourself.

Cad cam program code#

Good NC code will automatically improve edge quality, reduce dross, reduce hole taper, provide sharper corners, and add leads with the optimum length, style, angle, etc. If you want to ensure the job gets done right the first time and avoid secondary processes whenever possible, then an advanced software may be the answer.

What kind of part quality can I expect to see?. Using collision avoidance with plasma and laser helps reduce costly cutting head damage due to impact. If you’re looking to decrease pierce-count and thereby lower the cost of consumables, then consider whether the software offers options such as common line cutting, chain cutting, or bridge cutting.īetter part quality from built-in process expertise leads to less secondary part clean up. Even an improvement of just a few percent increase in material usage can add up to big savings – so advanced software can often pay for itself fairly quickly. This is due to the sophisticated algorithms and optimization techniques that are utilized with automatic nesting, plus other features, such as plate inventory management and work order processing. You will likely see an instant improvement in material utilization when switching to a more advanced software. What kind of material savings can I expect?. How many different screens does it require? Do you have to switch between programs to complete the job? If the software is designed for productivity, your team will be up and running faster, and will be able to complete their work in fewer steps. Consider whether the software interface is intuitive and easy to understand. Some programs are better designed than others. With entry-level software you may only have control over a single machine. Additionally, CAM software can support virtually all machine brands and models. You may also have control over combination punch, drilling, bevel cutting, and more. With advanced software you’ll be able to consolidate all of your programming into a single software solution, including support for multiple cutting processes such as plasma, laser, oxyfuel, and waterjet. Will the software support all of my machines and applications?. Here are some of the factors that you’ll want to consider: There are many different CAD/CAM nesting software solutions to choose from, ranging from entry-level, hobbyist programs, all the way up to advanced-level, enterprise packages.

0 kommentar(er)

0 kommentar(er)